efi facilities efi facilities

Location: Our plant and offices are in

the Cocoa Industrial Park; ½ mile north of

the Beachline Expressway (SR. 528), and ½ mile west

of U.S.1. We are also on the Florida East Coast Railroad.

Click here for map

Heavy Industrial Fabrication and Large

Machining Capabilities: EFI

has the facility, equipment, and manpower to build

small to very large machined parts, fabricate light to

heavy weldments and to provide precision installation of

motors, bearings, shafting and other power transmission

equipment. We also build, install, wire and test a wide

variety of 3 phase motor control panels, solenoids, limit

switches, etc. for the variety of equipment constructed in

our shop.

Railroad Spur: We have installed a railroad spur of the

Florida East Coast Railroad that dead ends 150 feet inside

the plant. EFI has shipped five overhead cranes via rail,

each weighing 150,000 pounds with an average length of 112’.

Each of these shipments required one main car and two idler

cars.

Plant Area: The building is a Republic

Steel metal building with a 30’ high, 330’ long,

and 65’ wide

clear span. There are 5 bridge cranes; 20 ton capacity, 10

ton, 5 ton, 3 ton and 2 ton as well as several 2 ton jib

cranes. Additionally, there is a 120’ long x 65’ wide

steel storage area with its bridge crane transporting steel

into the plant. Total length of crane runways is 450’.

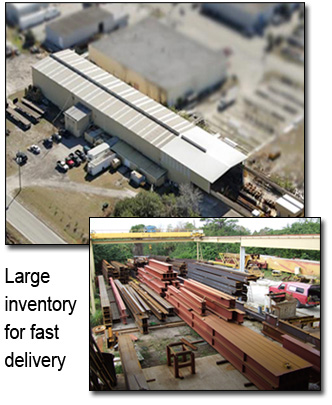

Inventory: EFI stocks a full compliment

of structural, mechanical and electrical components for overhead

cranes. Seven day delivery of cranes up to 10 ton x 60’ span

is readily available.

Fabrication Area: The plant has a number

of EFI designed and built specialized pieces of equipment

that contribute to highly efficient and accurate construction

of bridge cranes and fabrication of large steel weldments.

These include EFI’s “Charmin” box

girder assembly and semi-automated welding machine, EFI’s “Scorpion” traveling

weld and work station, swing

out 3 ton capacity monorail system and traveling type

large assembly bed beams.

Burning Department: The oxy-acetylene burning table is 40’ long

x 9’ wide with 6 torches for stripping and one cross

travel torch. This machine is capable of cutting cambers

in plates (for cambered box girders). We typically flame

cut these plates with a 2-mile radius for camber. We have

burned plates to build box section girders up to 96” high

by 36”wide, up to 132’ long, weighing as much

as 60,000 pounds.

Welding

Department: We have 5 wire feed welders for steel

and one for aluminum. One gas powered MILLER DC Welder and

three stick welders. One of the welders is mounted to the

Scorpion traveling workstation and

two are mounted to monorails. EFI has performed a considerable

amount of welding for NASA, Lockheed, the U.S. Navy, TVA,

Boeing, etc. Welding

Department: We have 5 wire feed welders for steel

and one for aluminum. One gas powered MILLER DC Welder and

three stick welders. One of the welders is mounted to the

Scorpion traveling workstation and

two are mounted to monorails. EFI has performed a considerable

amount of welding for NASA, Lockheed, the U.S. Navy, TVA,

Boeing, etc.

Fit-Up and Assembly: EFI has built many

different types of equipment over the last 42 years. These

include: overhead traveling electric bridge cranes from ½ ton

to 40 ton; cab, floor or radio controlled up to 130’ span,

ground support equipment for NASA and most major aerospace

and airline companies. Some of the more notable items include

engine stands for the RB211 Rolls Royce engine, thrust reverser

stands and other specialty items: 600 ton capacity box girders,

special equipment for aluminum smelting plants including

80,000 pound capacity conveyors, 100,000 pound capacity transfer

cars, special imprinting equipment, ground support equipment

for the Kennedy Space Center including an 18,000 pound device

used to rotate the Space Shuttle satellite payload canister

from horizontal to vertical and special heavy duty load beams.

Electrical Department: Three phase panels

are designed and built on site including reversing starters,

variable frequency controls, wound rotor primary and secondary

controls, eddy current brakes, limit switches and safety

devices for machines having several motors. We prepare our

own electrical engineering and schematic drawings. We have

in-house UL certification of our control panels available.

Prep and Painting: EFI has a large Wheel-a-Brator

for cleaning beams up to 38” deep as well as small

steel parts. This provides for excellent paint application

on our cranes and runway systems.

EFI has several airless and conventional spray systems for

applying a wide variety of coating systems. We can provide

high-performance epoxy and urethane outdoor coating systems

as well as shop coat primers and alkyd enamel coatings.

|